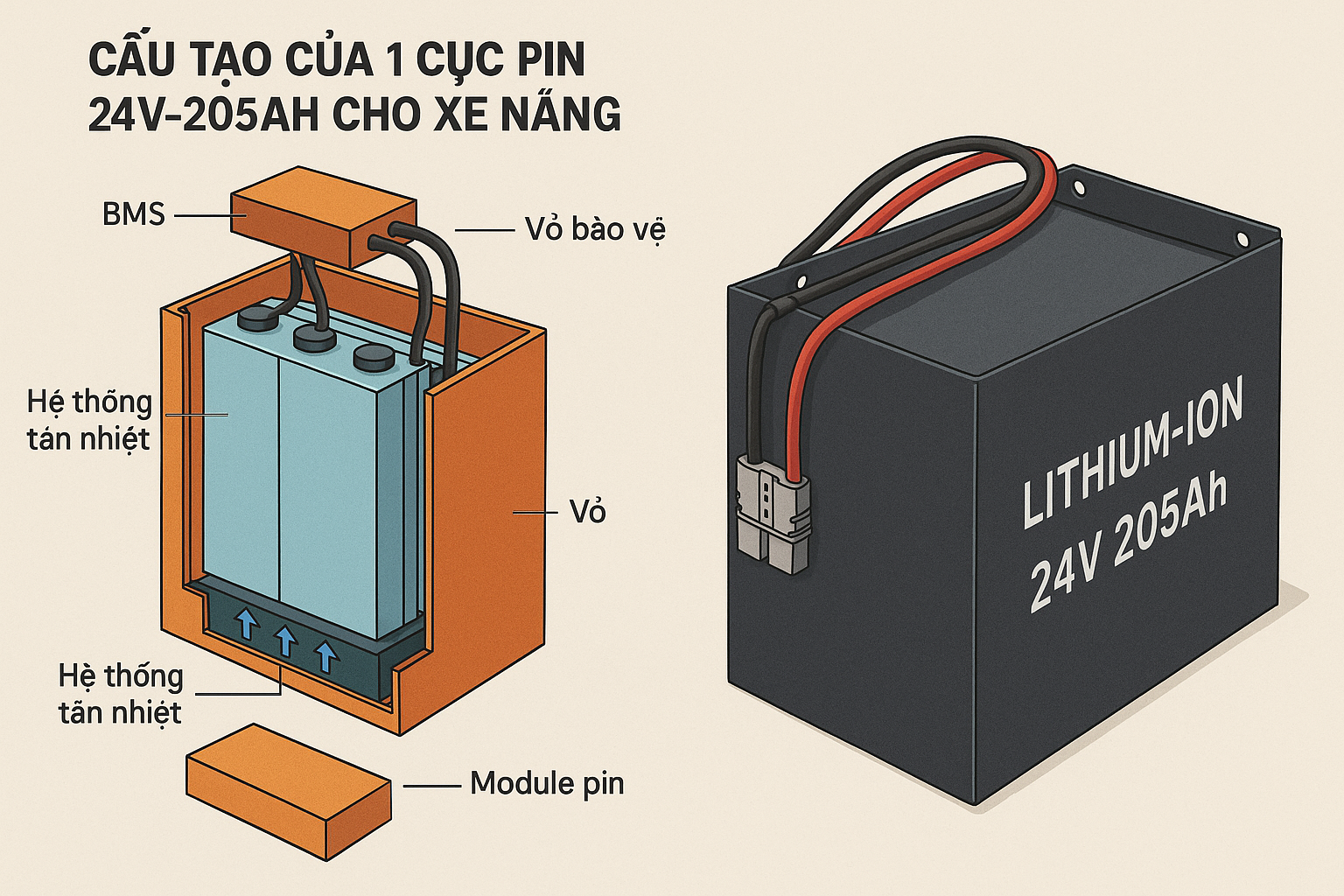

STRUCTURE OF A 24V-205AH BATTERY FOR FORKLIFTS

A 24V-205Ah battery for forklifts (especially electric forklifts) is typically either a lithium battery or a lead-acid battery, depending on the technology. Each type has a different structure, but to provide the most accurate answer, here’s the basic construction:

-

With Lithium Battery (LiFePO₄ or NMC)

Main components of a 24V-205Ah battery pack:

-

Battery cells:

A single lithium cell has a nominal voltage of about 3.2V (LiFePO₄) or 3.7V (NMC).

To create 24V, multiple cells are connected in series:-

Example with LiFePO₄: 24V/3.2V ≈ 8 cells (actually 8S = 25.6V).

-

If using NMC: about 7S (7 × 3.7V = 25.9V).

Capacity of 205Ah is achieved by connecting multiple parallel branches of cells.

-

-

Battery modules:

Small cells are grouped into modules for easier management and maintenance. -

BMS (Battery Management System):

Manages the battery: balances cells, and protects against overcharge, overdischarge, overcurrent, and overheating. -

Protective casing:

Made of durable metal, resistant to vibration, impact, water, and oil (rated IP54–IP67 depending on model). -

Cooling system:

Some packs have fans, thermal gel, or ventilation slots to ensure stable operation. -

Cables and connectors:

High-power cables (often Anderson, REMA standard) and charging ports.

-

With Lead-Acid Battery (Flooded/AGM/Gel)

Construction of a 24V-205Ah battery pack:

-

Individual cells:

Each cell provides 2V (single cell) or 6V/12V (pre-assembled types).

Typically 12 × 2V cells are connected in series to achieve 24V. -

Lead plates:

Positive and negative plates made from lead alloy coated with active material (e.g., lead oxide). -

Electrolyte solution:

Diluted sulfuric acid (H₂SO₄).

For AGM/Gel types: the solution is absorbed into fiberglass mats or transformed into gel. -

Battery casing:

Made of acid-resistant, impact-resistant ABS or PP plastic. -

Gas release system:

One-way gas release valves (for AGM/Gel types). -

Cables and connectors:

Similar to lithium batteries, industrial-grade connectors are used.

Quick comparison:

| Factor | Lithium Battery | Lead-Acid Battery |

|---|---|---|

| Weight | 40–50% lighter | Heavier |

| Lifespan | 3000–5000 cycles | 1000–1500 cycles |

| Maintenance | No water refilling needed | Requires water maintenance (if flooded) |

| Investment cost | Higher | Lower |

| Safety | Requires BMS for protection | Less risk of fire/explosion |