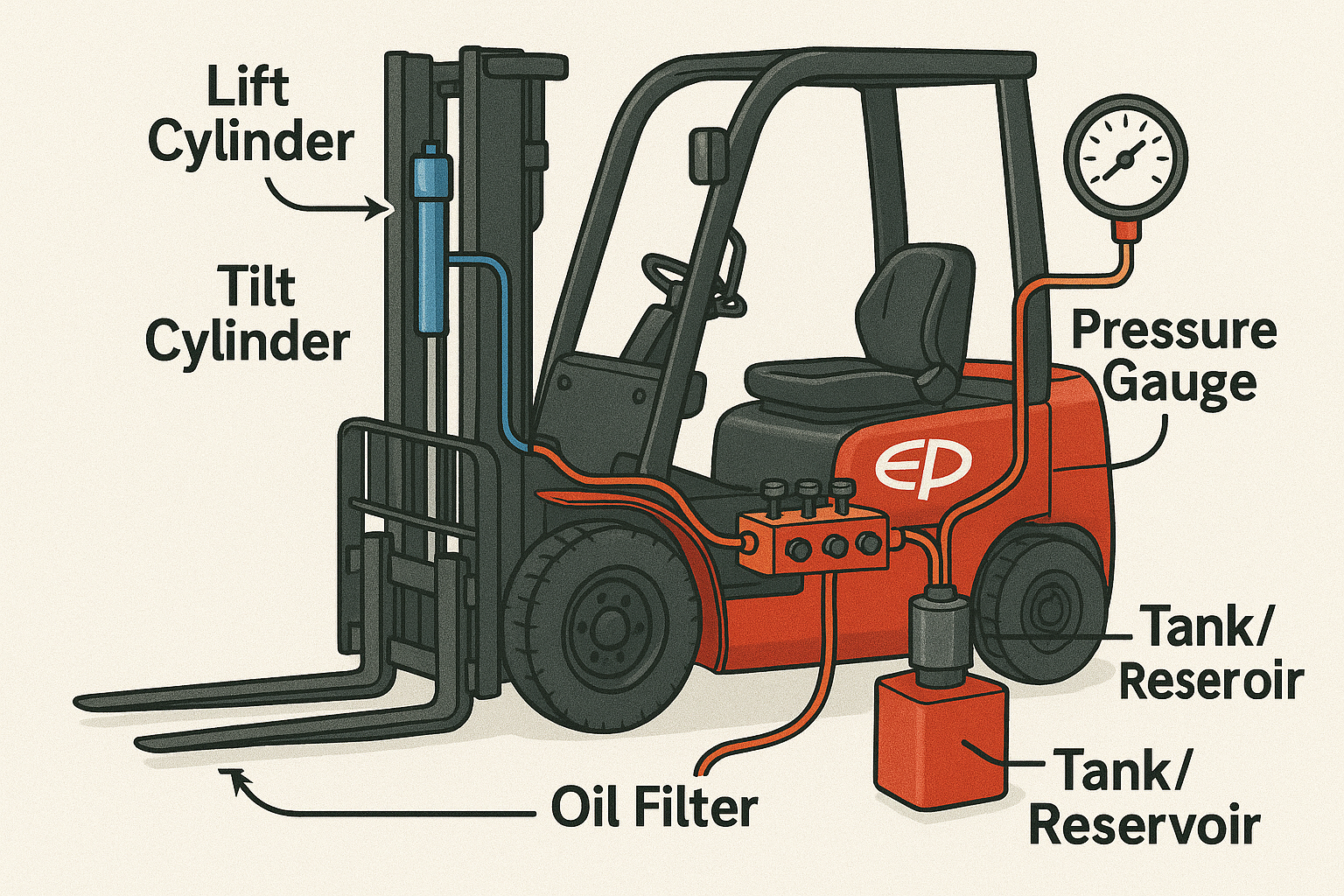

Hydraulic System on Forklifts: Structure, Operating Principle, and Troubleshooting

I. Overview of the Hydraulic System on Forklifts

The hydraulic system is the “heart” of the lifting and control mechanism in forklifts. It operates based on Pascal’s principle, transmitting force through fluid (hydraulic oil) to perform lifting, tilting, fork shifting, pushing, etc.

II. Structure of the Hydraulic System

-

Hydraulic Pump:

-

Function: Generates oil pressure and supplies it to the system.

-

Position: Attached to the engine (for diesel forklifts) or electric motor (for electric forklifts).

-

Types:

-

Gear Pump (common, low cost)

-

Piston Pump (high pressure, precise)

-

Vane Pump (rarely used on forklifts)

-

-

-

Control Valves:

-

Function: Regulate and distribute hydraulic oil flow to cylinders.

-

Types:

-

Lift Valve

-

Tilt Valve

-

Flow Control Valve

-

Safety Relief Valve

-

-

-

Hydraulic Cylinders:

-

Function: Convert oil pressure into mechanical (linear) motion.

-

Types:

-

Lift Cylinder

-

Tilt Cylinder

-

Side Shift Cylinder (if equipped)

-

-

-

Hydraulic Oil Tank (Reservoir):

-

Function: Store, cool, and settle impurities in the oil.

-

Note: Equipped with oil filters for clean oil supply.

-

-

Pipes and Hydraulic Hoses:

-

Materials: High-pressure steel pipes or reinforced rubber hoses.

-

Function: Transport oil to components and back to the tank.

-

-

Oil Filter:

-

Function: Filter impurities, keep oil clean, and protect pumps and valves.

-

-

Pressure Gauge:

-

Function: Display oil pressure for diagnostics and maintenance.

-

III. Operating Principle

-

When the operator pulls or pushes the control lever, signals are sent to the control valves.

-

The hydraulic pump pushes oil through the valves to the hydraulic cylinders.

-

Oil pressure acts on the pistons inside the cylinders, generating mechanical force:

-

Lift or lower the forks.

-

Tilt the mast forward/backward.

-

Move the forks or other optional functions.

-

-

When controls are released, oil returns to the tank, and the system returns to standby.

IV. Common Issues and Solutions

| Phenomenon | Cause | Solution |

|---|---|---|

| Slow or no lifting | Low oil, clogged filter, weak pump | Check and add oil, replace filter, inspect pump |

| Oil leakage | Damaged seals, cracked hoses | Replace seals, replace hoses |

| Forks drop after lifting | Faulty valve, scratched cylinder | Repair or replace valve/cylinder |

| Loud noise during operation | Dirty oil, damaged pump, air in system | Change oil, check pump, bleed air |

V. Maintenance Notes

-

Check oil levels periodically (usually every 1-3 months).

-

Replace oil filter every 500-1000 operating hours.

-

Regularly check for leaks and inspect cylinders and hoses.

-

Use hydraulic oil that meets the correct standards (typically ISO VG 46 or 68 depending on climate).