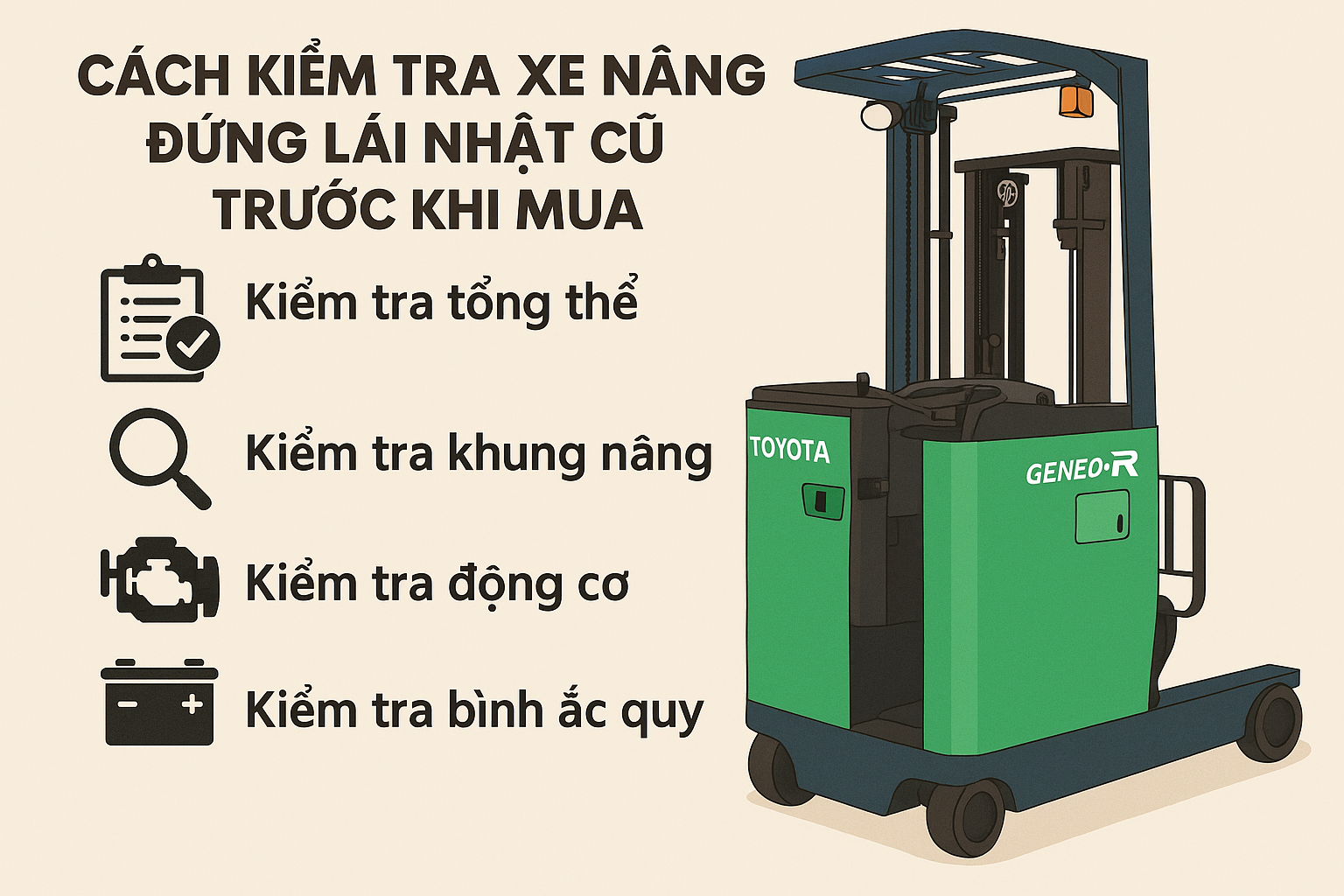

How to Inspect a Used Japanese Stand-On Forklift Before Buying

How to Inspect a Used Japanese Stand-On Forklift Before Buying

When buying a used Japanese stand-on forklift, careful inspection will help ensure quality and avoid potential risks later. Below is a detailed guide with important steps to consider.

Check the Exterior Overall

-

Mast and forks: Inspect carefully for bending, welding cracks, or signs of heavy impact.

-

Wheels: Check for wear, cracks, or uneven sinking of the rubber.

-

Paint and rust: Pay close attention to the undercarriage and wheel axles.

-

Operator’s platform: Ensure pedals and control levers are still responsive and not loose.

Check the Lifting System

-

Test lifting with about 70–80% of the rated load capacity.

-

Observe if the lifting/lowering speed is smooth and stable or jerky.

-

Listen for unusual noises from the hydraulic pump or mast bearings.

-

Check hydraulic cylinders for oil leaks.

Check the Electrical System and Battery

-

Battery or lithium pack: Measure voltage, check charging cycles, and fluid condition (for lead-acid).

-

Cables and connectors: Inspect for burns or oxidation.

-

Dashboard, horn, lights: Ensure they function properly.

-

For lithium batteries: Check the BMS (Battery Management System) for error alerts.

Check Steering and Driving Ability

-

Test drive on a flat surface to see if the forklift moves straight or drifts.

-

Check steering wheel or control handle for heaviness, delay, or strange noises.

-

Test forward, reverse, and sharp turns to evaluate maneuverability.

-

Inspect brakes during emergency stops.

Check Operating Hours and Software

-

Compare operating hours (hour meter) with the actual condition of the forklift.

-

Some Japanese brands such as Toyota and Nichiyu allow data checks via electronic control panels.

Test Real Operation

-

Run the forklift continuously for 15–20 minutes to assess performance.

-

Monitor motor and battery temperature; overheating may indicate wear.

-

Test cornering and continuous lifting to confirm stability.

Tips for Choosing a Used Japanese Stand-On Forklift

-

Bring along a forklift technician for accurate evaluation.

-

If unsure about the battery condition, hire a professional testing service.

-

Prioritize forklifts with fewer operating hours (<5,000 hours) and used in clean warehouses.

-

Negotiate for a warranty of at least 3–6 months on the battery and motor.

Conclusion

Buying a used Japanese stand-on forklift can save costs, but thorough inspection is crucial. If you need advice or a detailed checklist, contact us for the best support.