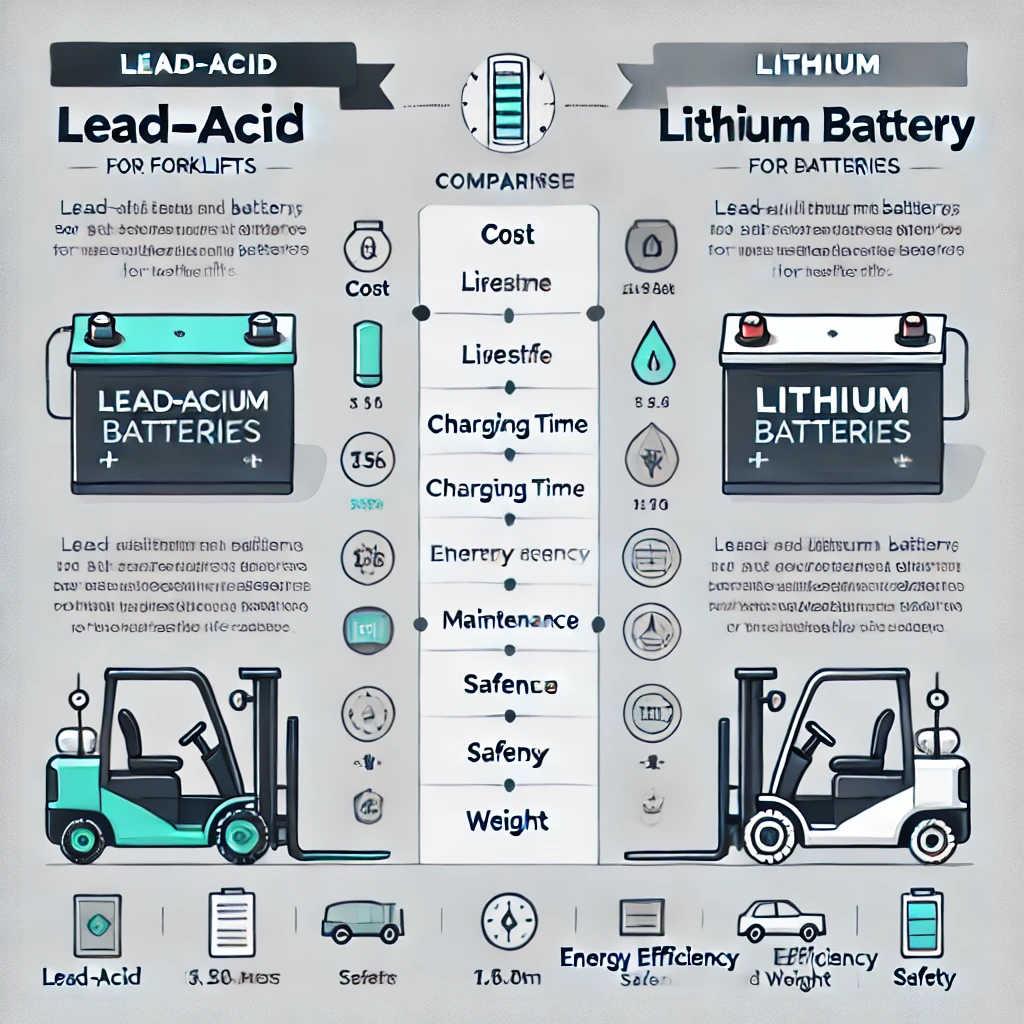

Comparison of Benefits Between Lead-Acid and Lithium Batteries in Forklifts

Lead-acid and lithium batteries are both used in forklifts, but they have different characteristics and performance. Below is a detailed comparison of the advantages and disadvantages of each battery type:

| Criteria | Lead-Acid Battery | Lithium Battery |

|---|---|---|

| Initial Investment Cost | Lower, suitable for limited budgets | Higher, but cost-effective in the long run |

| Lifespan | 3-5 years, about 1,000 – 1,500 charge cycles | 8-10 years, up to 3,000 – 5,000 charge cycles |

| Charging Time | 6-8 hours, requires cooling time | 1-3 hours, no cooling time needed |

| Maintenance | Regular maintenance required, checking electrolyte levels | Almost maintenance-free |

| Energy Efficiency | 70-80%, energy loss during charging | 95-98%, minimal energy loss |

| Depth of Discharge | Limited, easily damaged if discharged below 50% capacity | Can discharge deeply to 80-90% without harm |

| Temperature Impact | Significant efficiency loss in low temperatures | Stable performance under various temperature conditions |

| Weight | Heavier, helps balance forklift counterweight | Lighter, may need additional counterweight if required |

| Safety and Environmental Impact | Risk of acid leakage and hazardous gases | Safer, no acid leakage, less toxic |

| Opportunity Charging | Not feasible, affects battery lifespan | Feasible, no harm to the battery |

| Recycling Value | High recycling capability | Complex recycling process, but less toxic |

Conclusion:

-

Lead-Acid Battery: Suitable for small businesses with lower investment needs, non-continuous shifts, and no need for fast charging. However, regular maintenance and monitoring of deep discharges are necessary.

-

Lithium Battery: Ideal for large enterprises requiring high performance, continuous shifts, and long-term cost optimization. Although the initial investment is higher, its efficiency and long lifespan reduce overall operational costs.